Atlas of cast metal-matrix composites structures

|

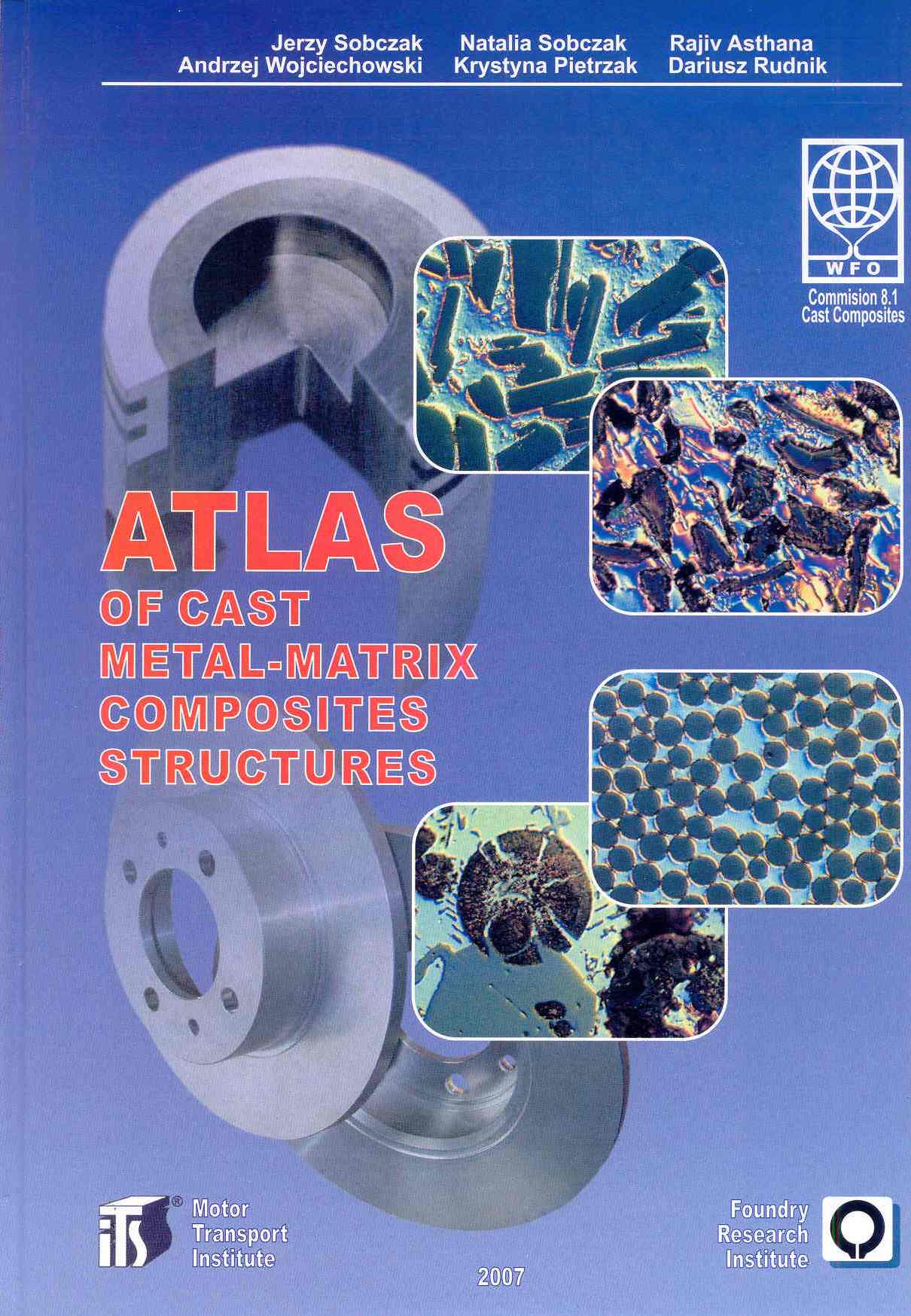

ATLAS OF CAST METAL-MATRIX COMPOSITES STRUCTURES Jerzy Sobczak, Natalia Sobczak, Rajiv Asthana, Andrzej Wojciechowski, Krystyna Pietrzak, Dariusz Rudnik ISBN 978-83-60965-00-9 Year of publication: 2007 Number of pages: 144 Price: 100 zł |

|

List of contents

|

This publication is an atlas of composite materials’ metal structures of non–ferrous matrix, in majority manufactured and tested during the last decade by the authors of this book, both domestically – at the Foundry Institute in Cracow and Motor Transport Institute in Warsaw, and abroad, especially at the Composite Centre of the Wisconsin University, Milwaukee, USA. In comparison with the monolith material (metal, alloy), the structure of heterogenic material, especially that of the composite material, gets enriched and complicated by the presence of the second – beside the matrix - component: the reinforcement phase. The degree of complexity of the evaluation of such structures increases, which can cause the loss of the required degree of adequacy of the relation between the matrix chemical composition, type and the element of the reinforcement content, technological parameters of the composite synthesis process, its properties and structure. Hence the importance of the availability of the appropriate information on the structures of the materials tested in connection with the initial attributes of their creation and detailed definition of the conditions of their manufacture. The atlas contains metal composite materials’ structures based on the aluminium, copper, zinc, lead and partly nickel as well as magnesium, obtained mainly in Poland. Composites were reinforced with the particles of fly ashes, graphite, silicon carbide, aluminium oxide), short fibre (based on the aluminium oxide and carbon felt) and the long carbon fibre. There are also structural pictures shown of the gasars (new group of composites with the gaseous reinforcement phase) as well as aluminium nanocomposites obtained for the first time domestically. The analysis of the structural specifics of each type of the composite has been augmented with the composite types' description, method of manufacture and service properties, proved both experimentally and potential. There is a detailed description of the typical structural flaws of the cast metal composites. |